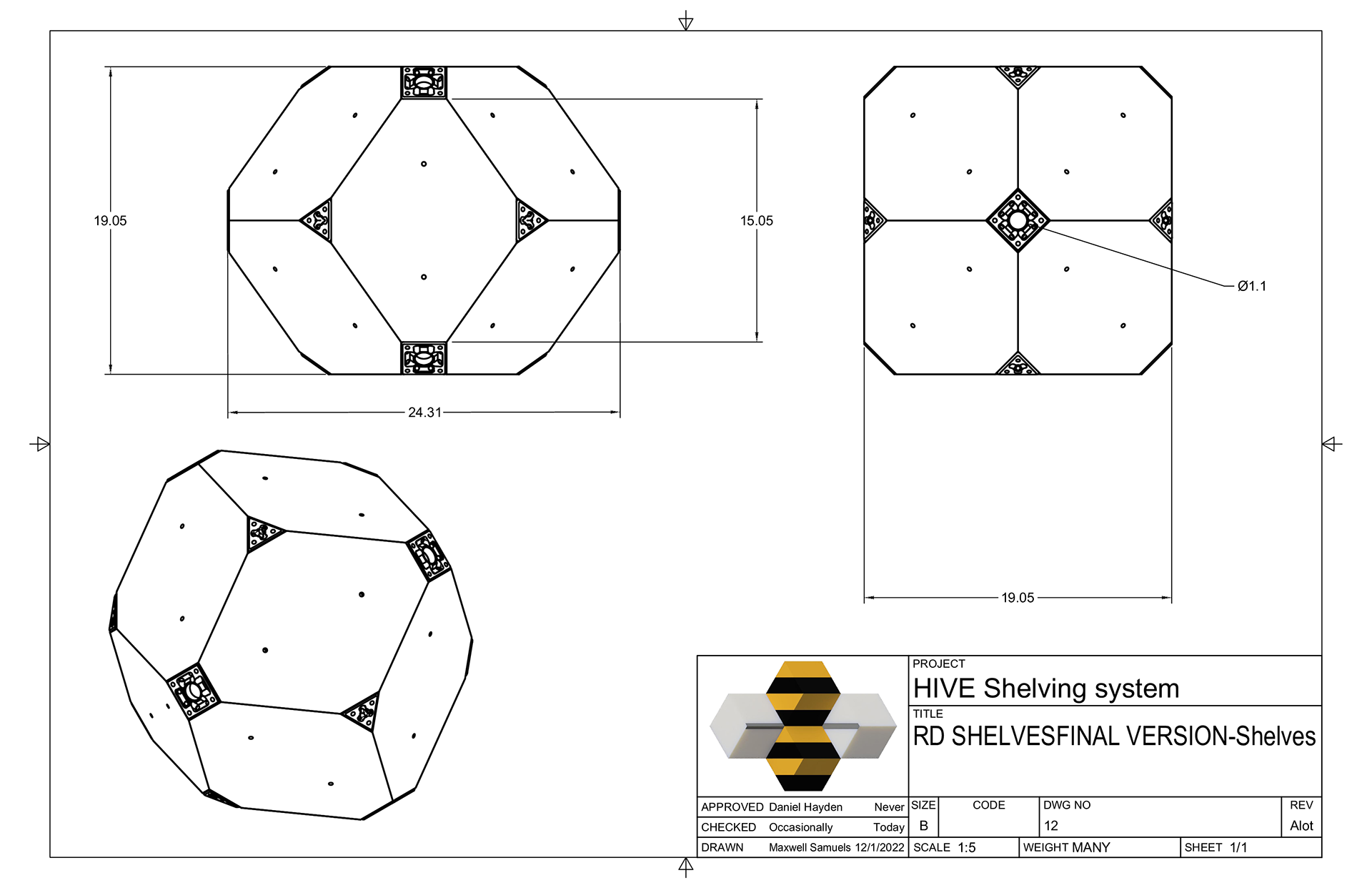

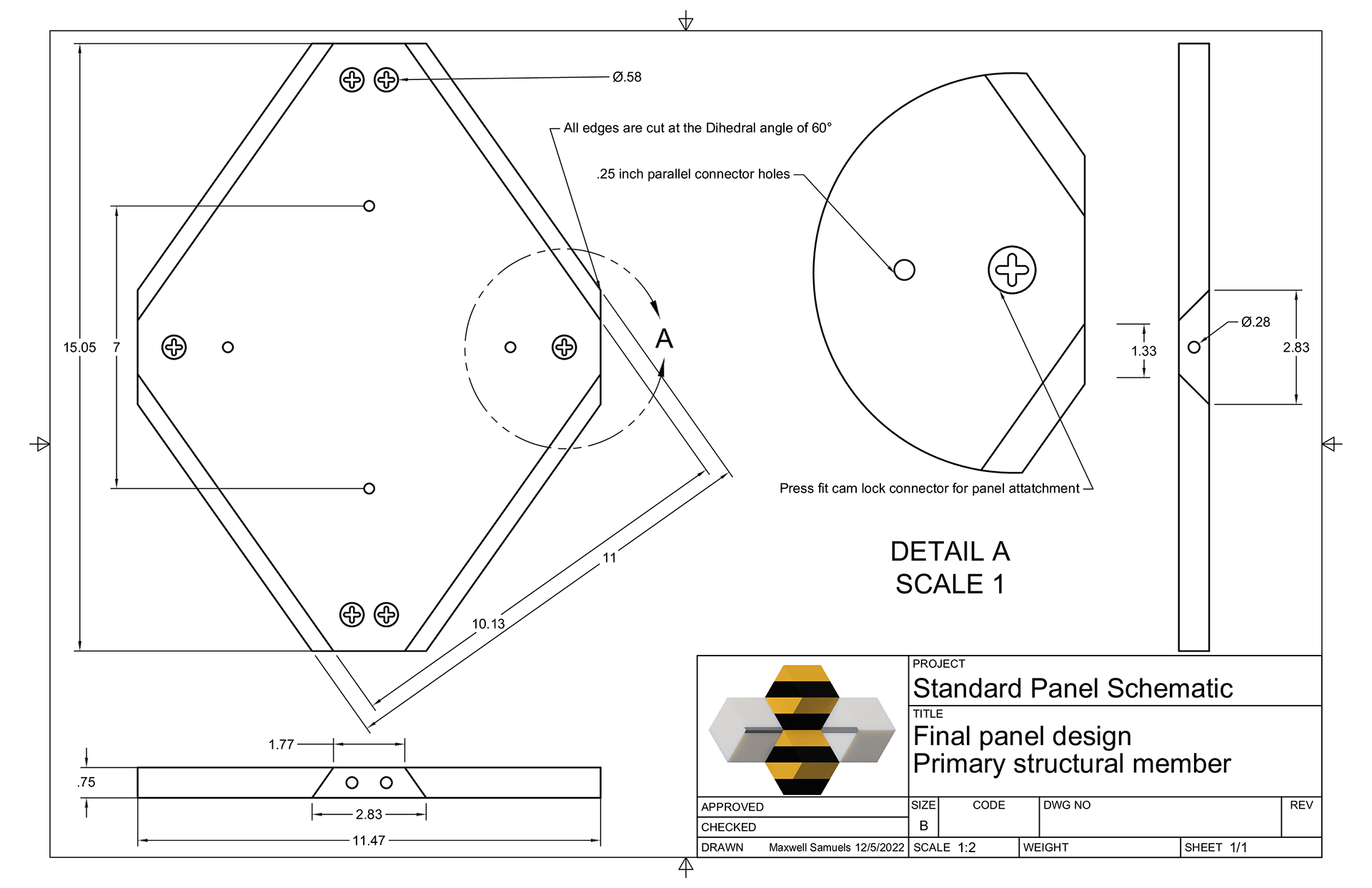

Don't tell anyone but I weigh 210 LBS. The panel on the front with the Cam locks on the outside is meant so that you can place all 12 possible panels into place. (The last panel would not have its cam locks exposed on the normal design, so one of these is needed.)

My classmate Tobi.

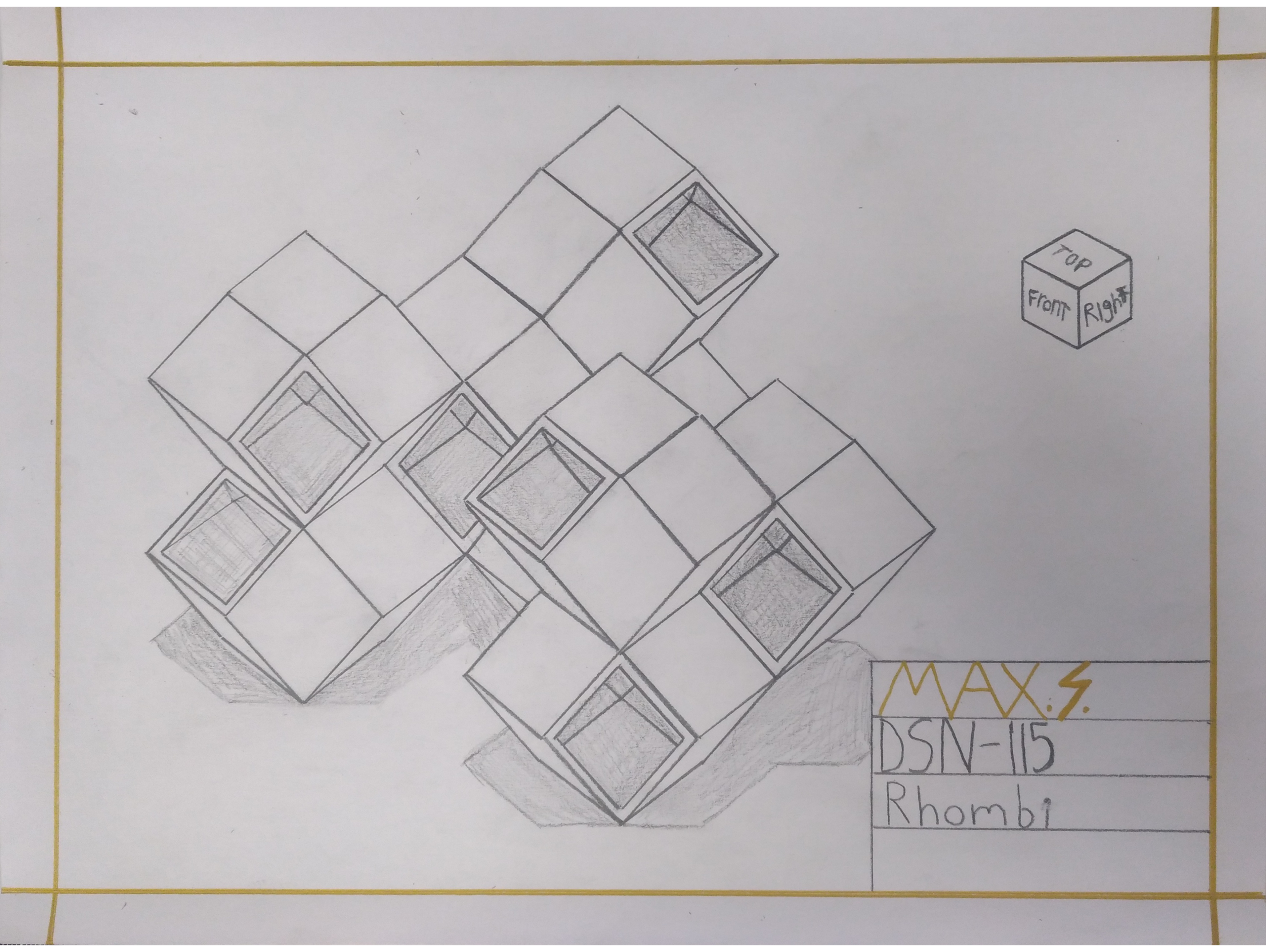

An early prototype that wasn't stable

The first wood version to prove this was possible

This prototype demonstrated that I could flat pack the design, but it couldn't be taken apart easily because it used screws

Test of the final prototype. This was to prove that the CAM lock system worked.

Accepted into the Curated NYC Design week 2023 Student Furniture Showcase