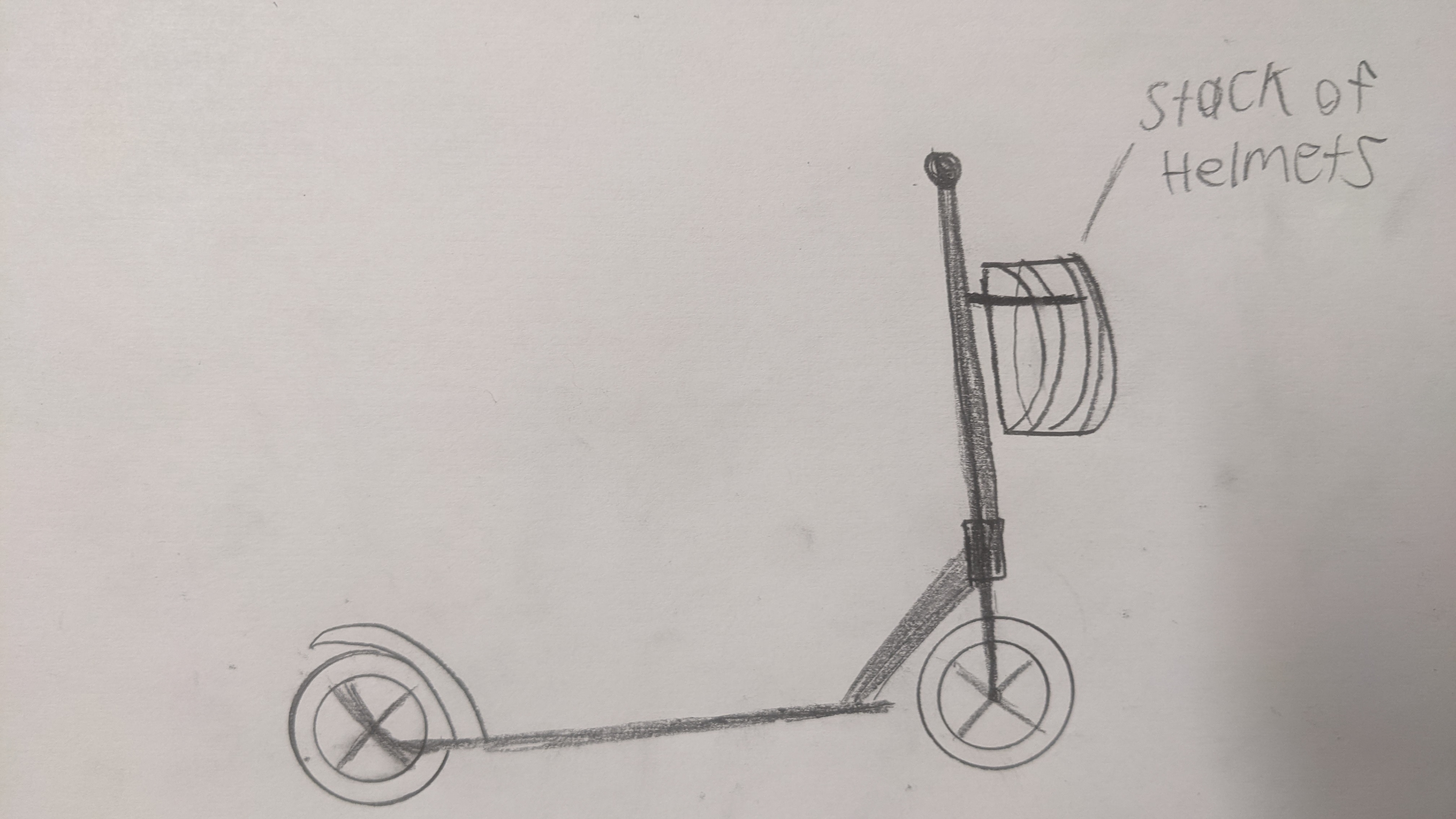

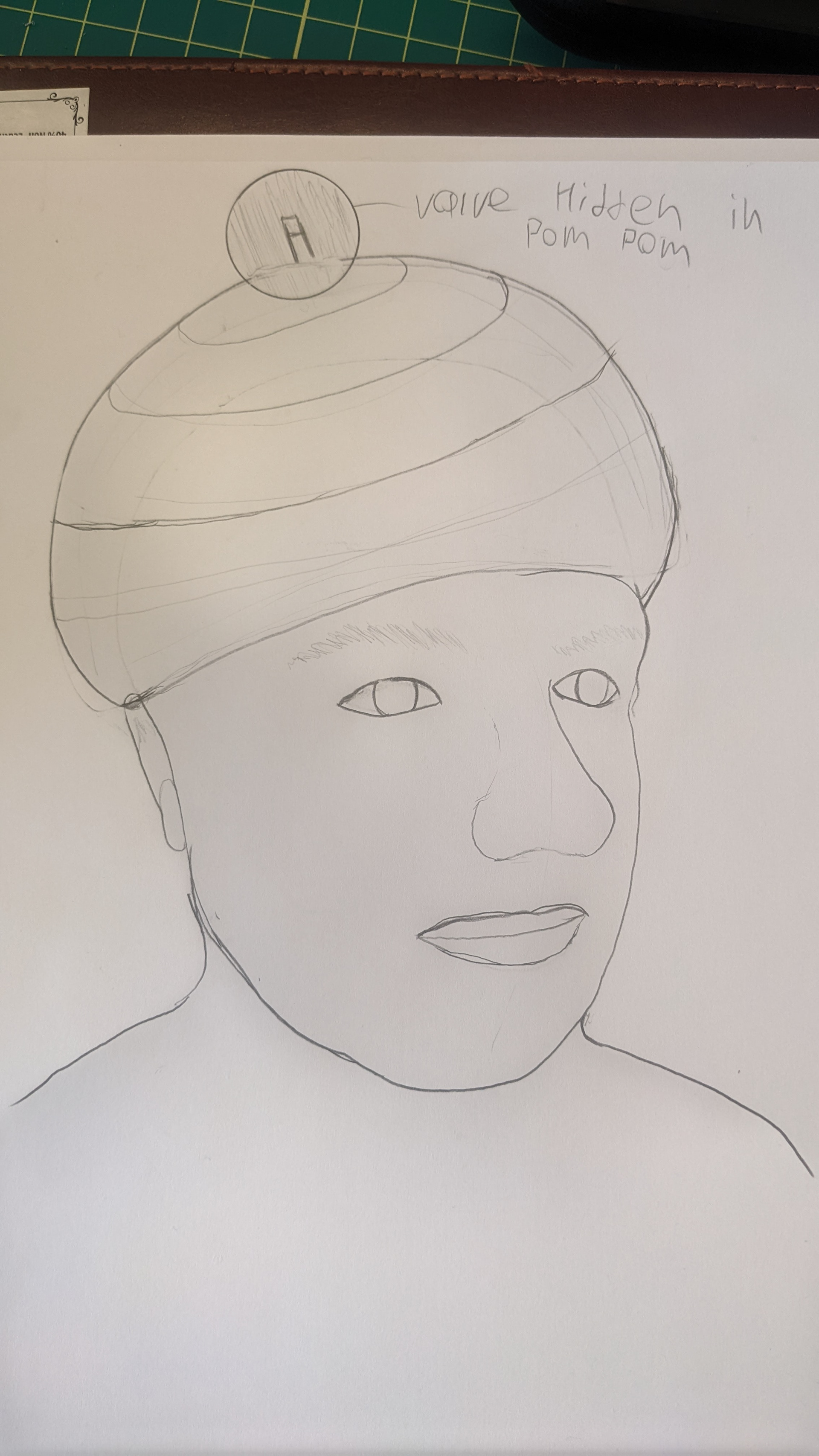

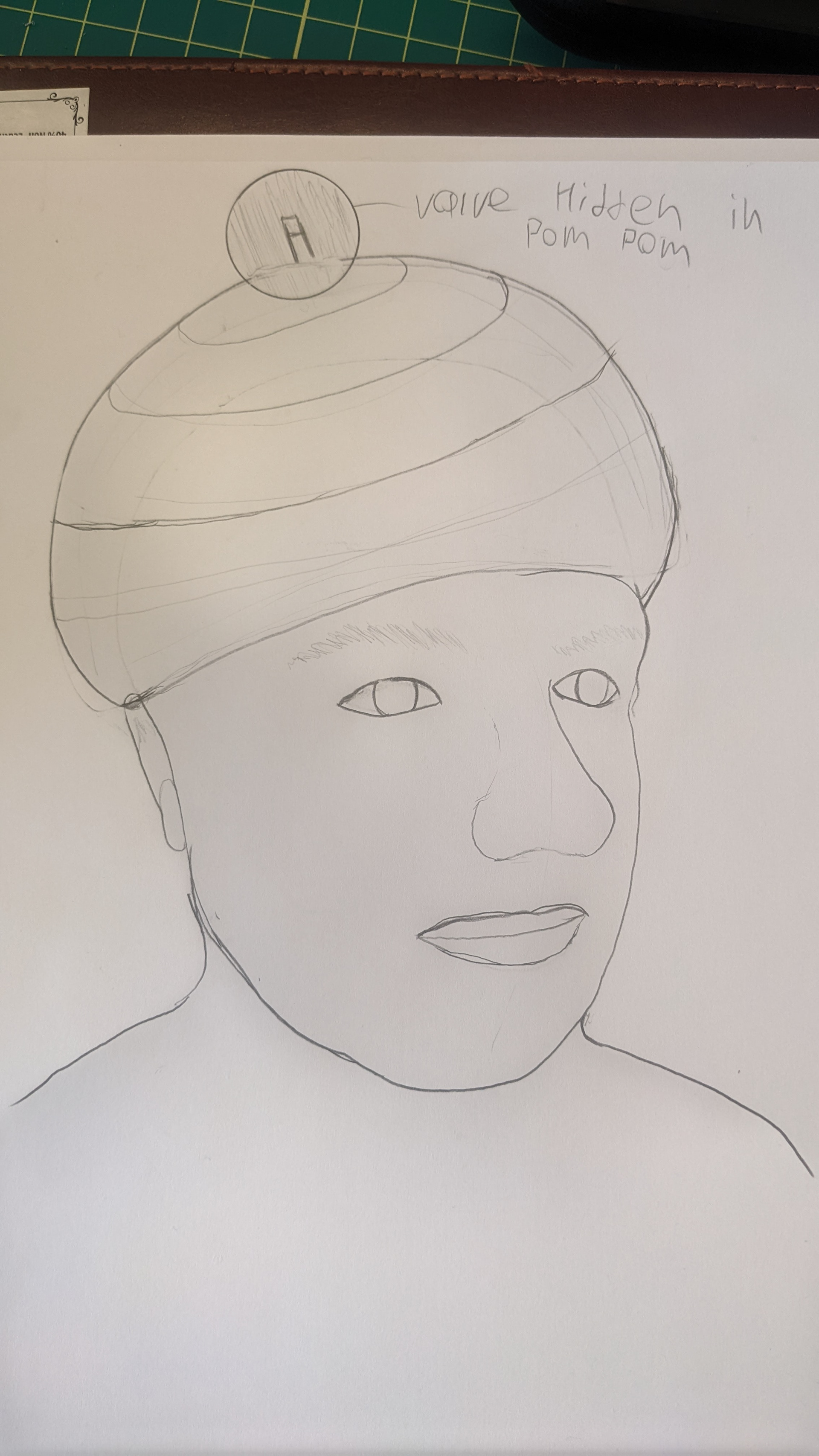

This was a poster I made to describe my project

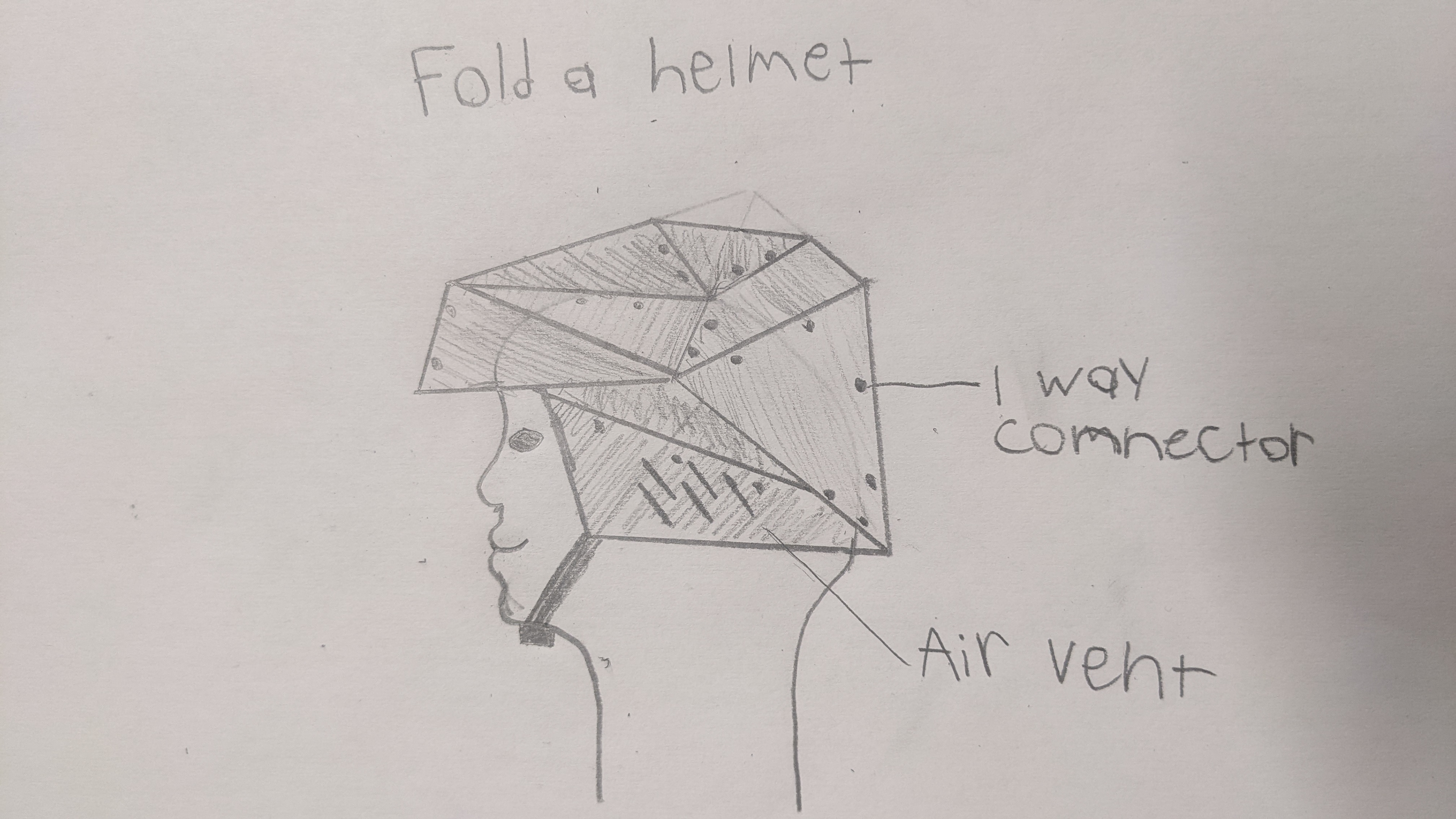

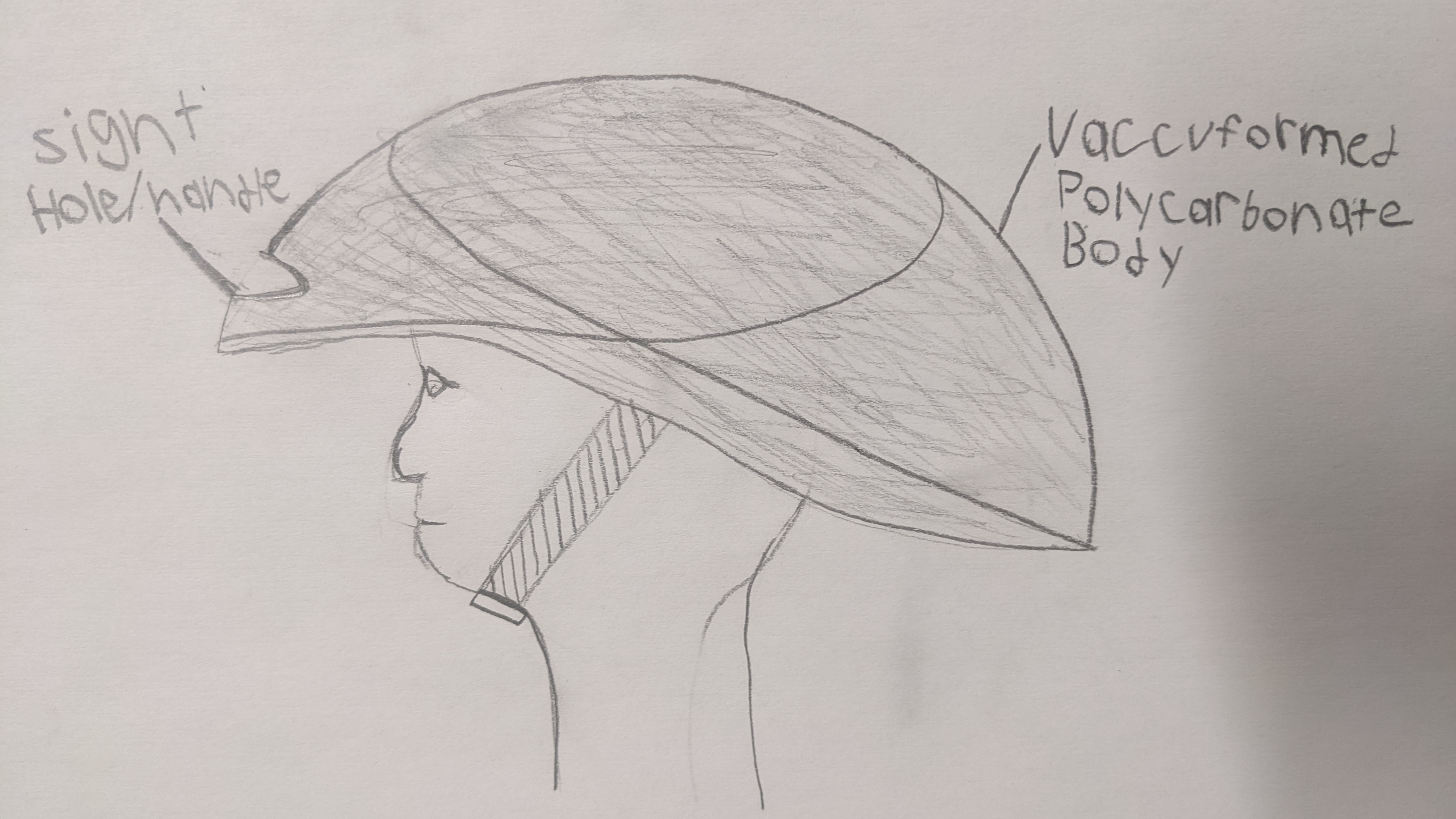

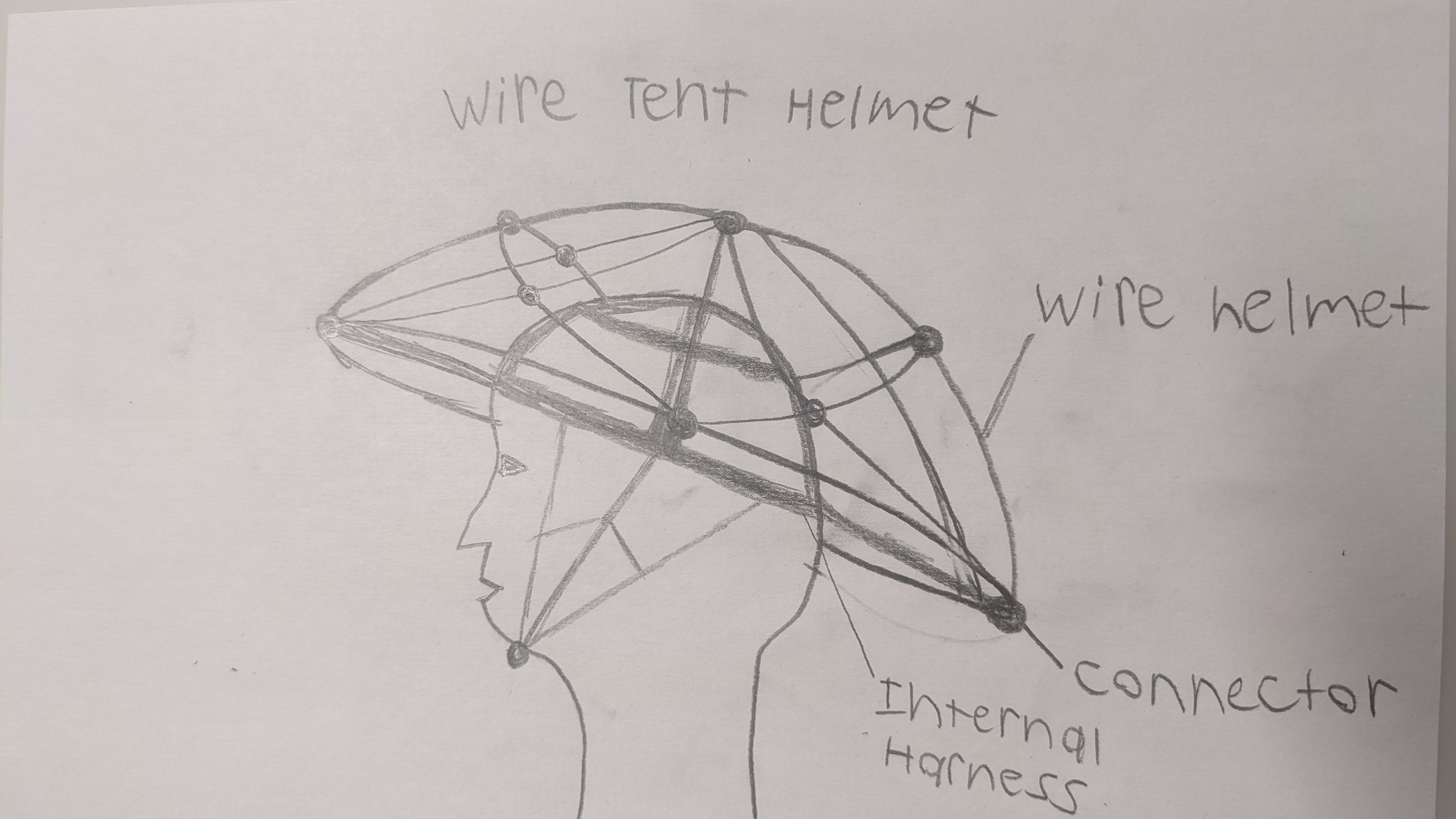

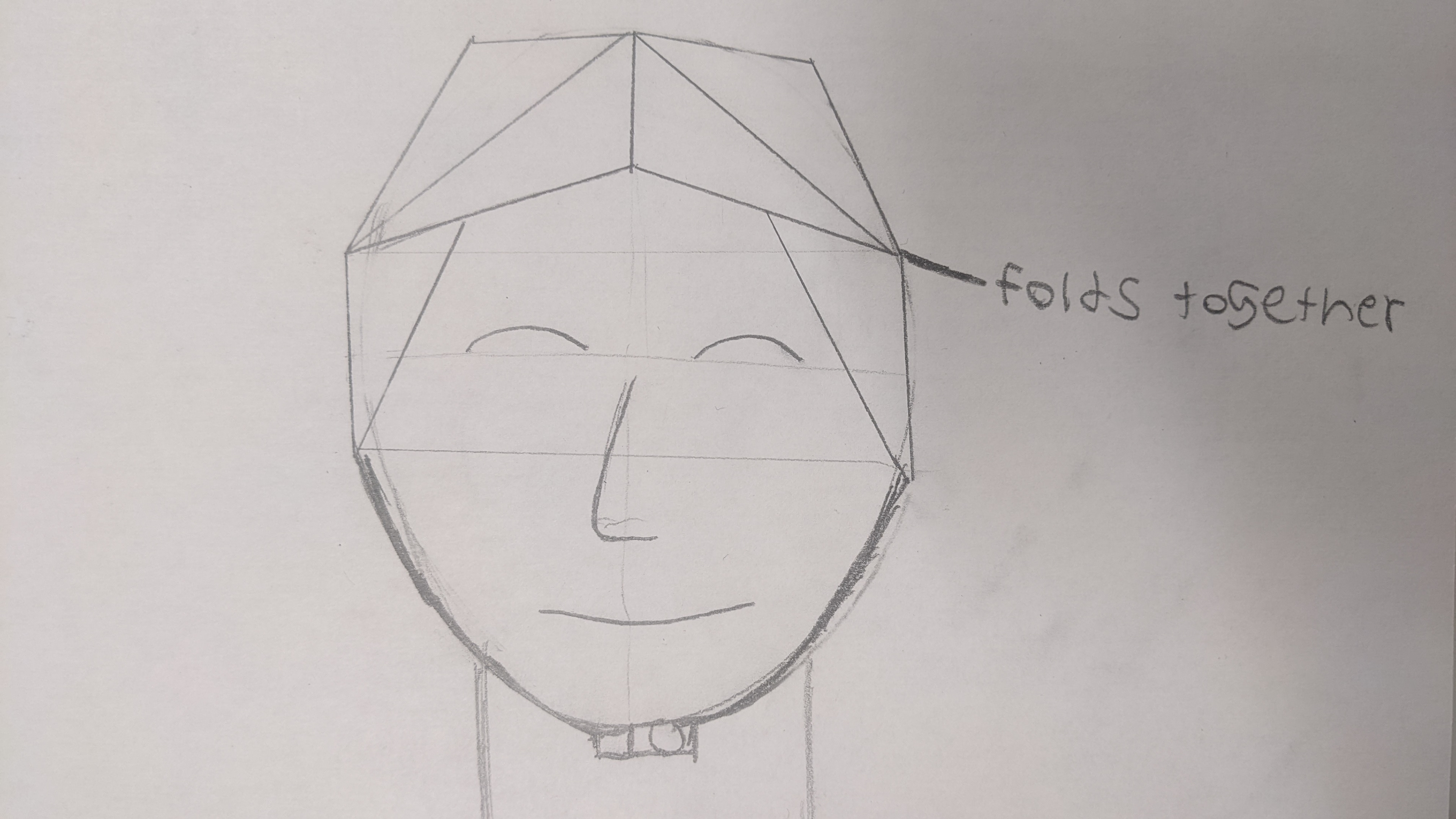

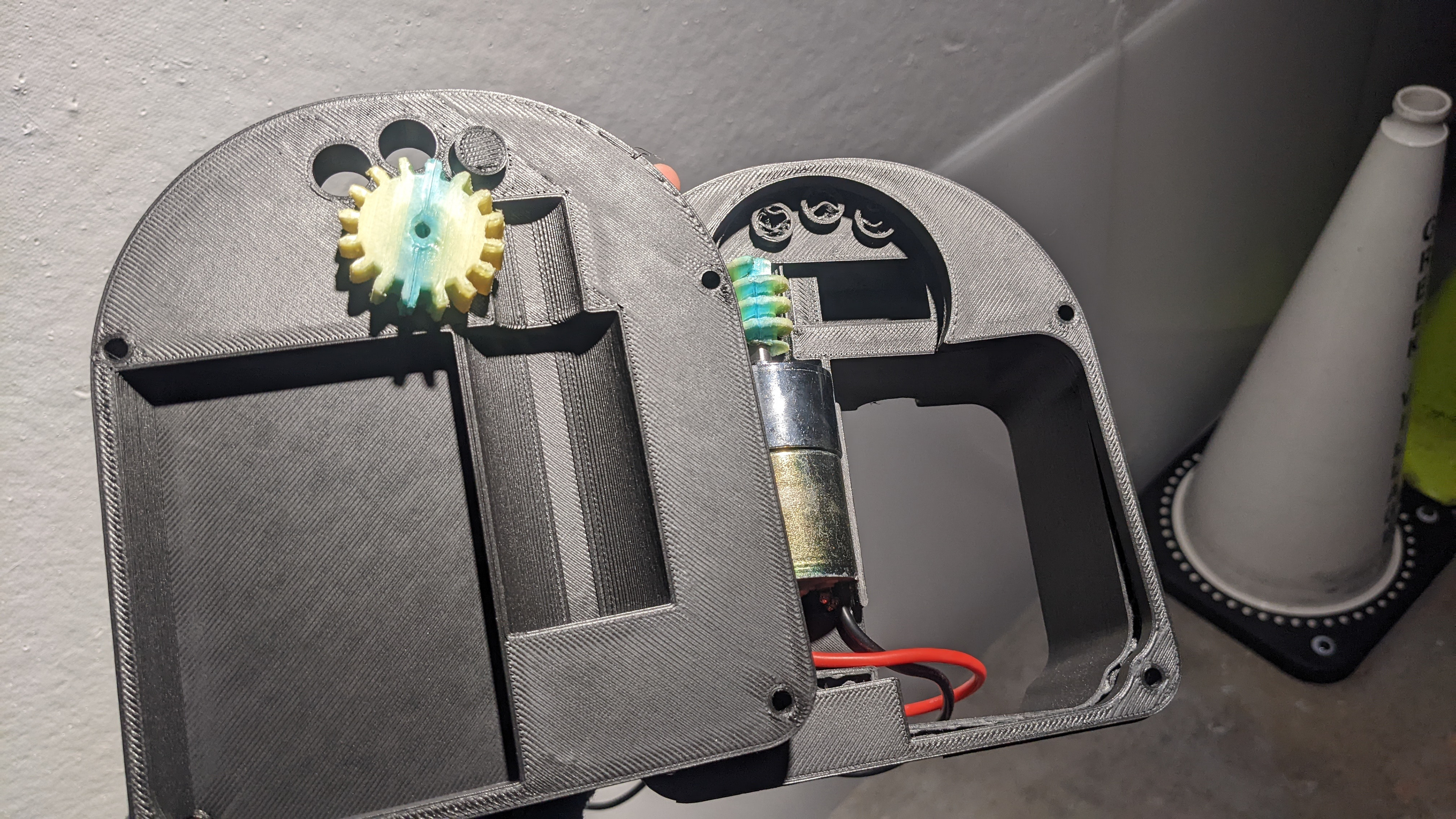

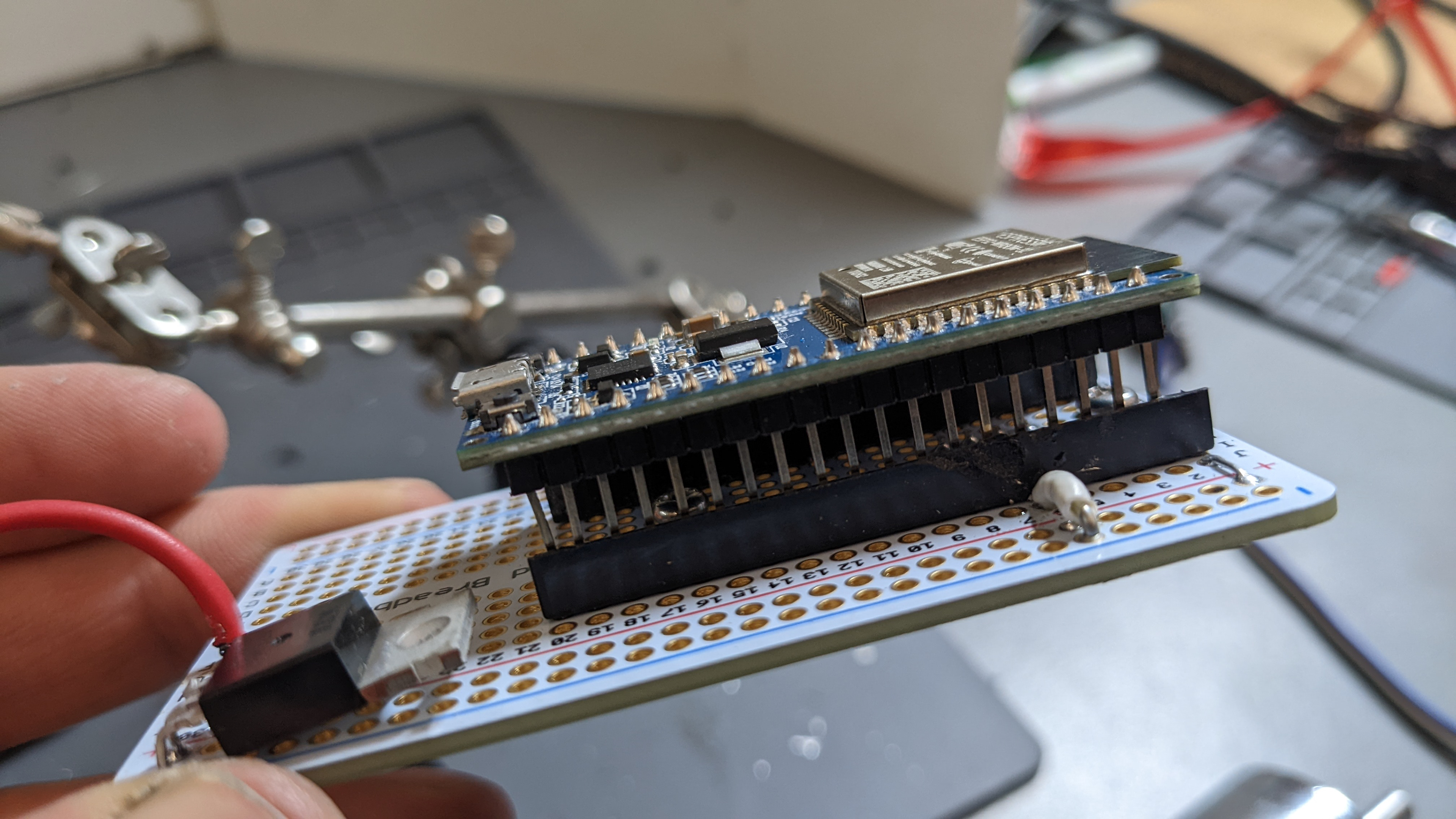

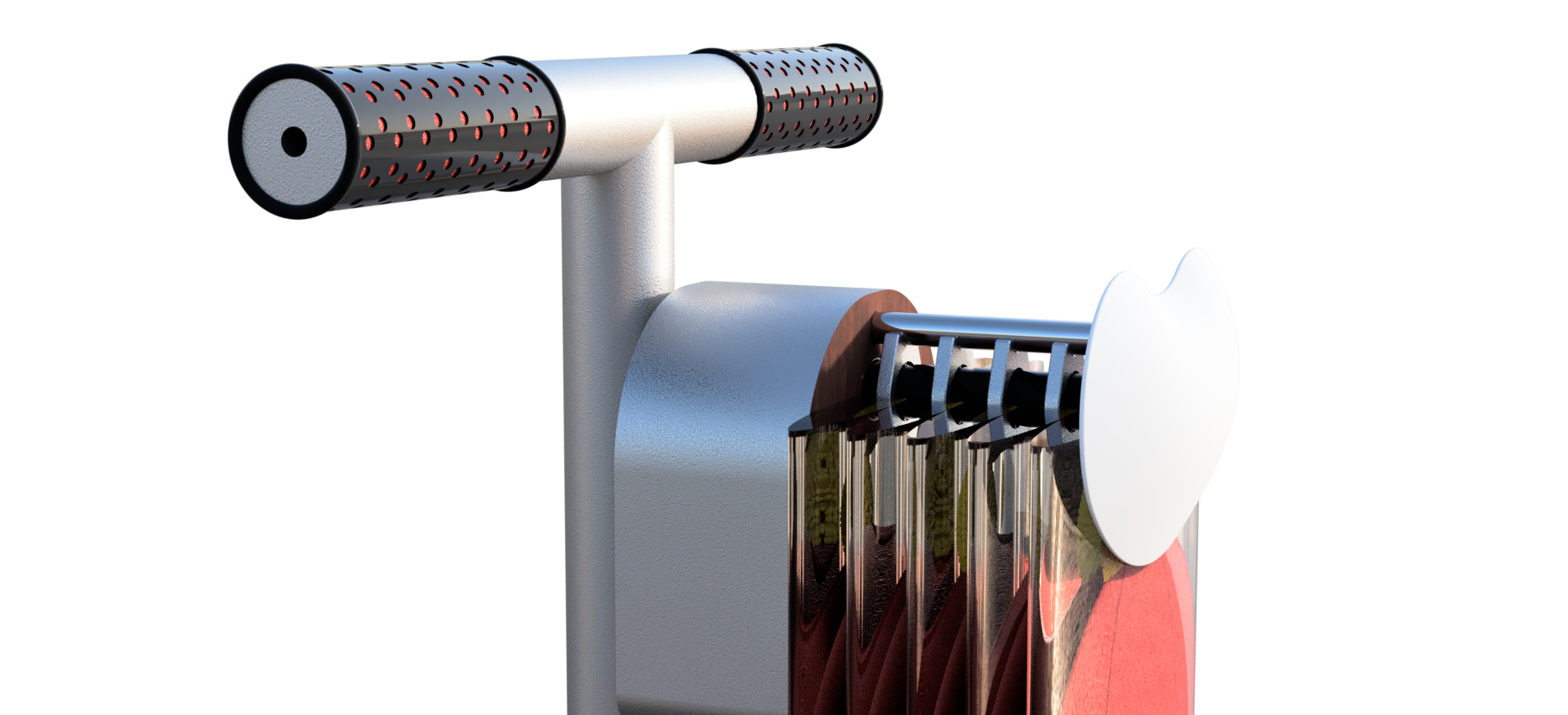

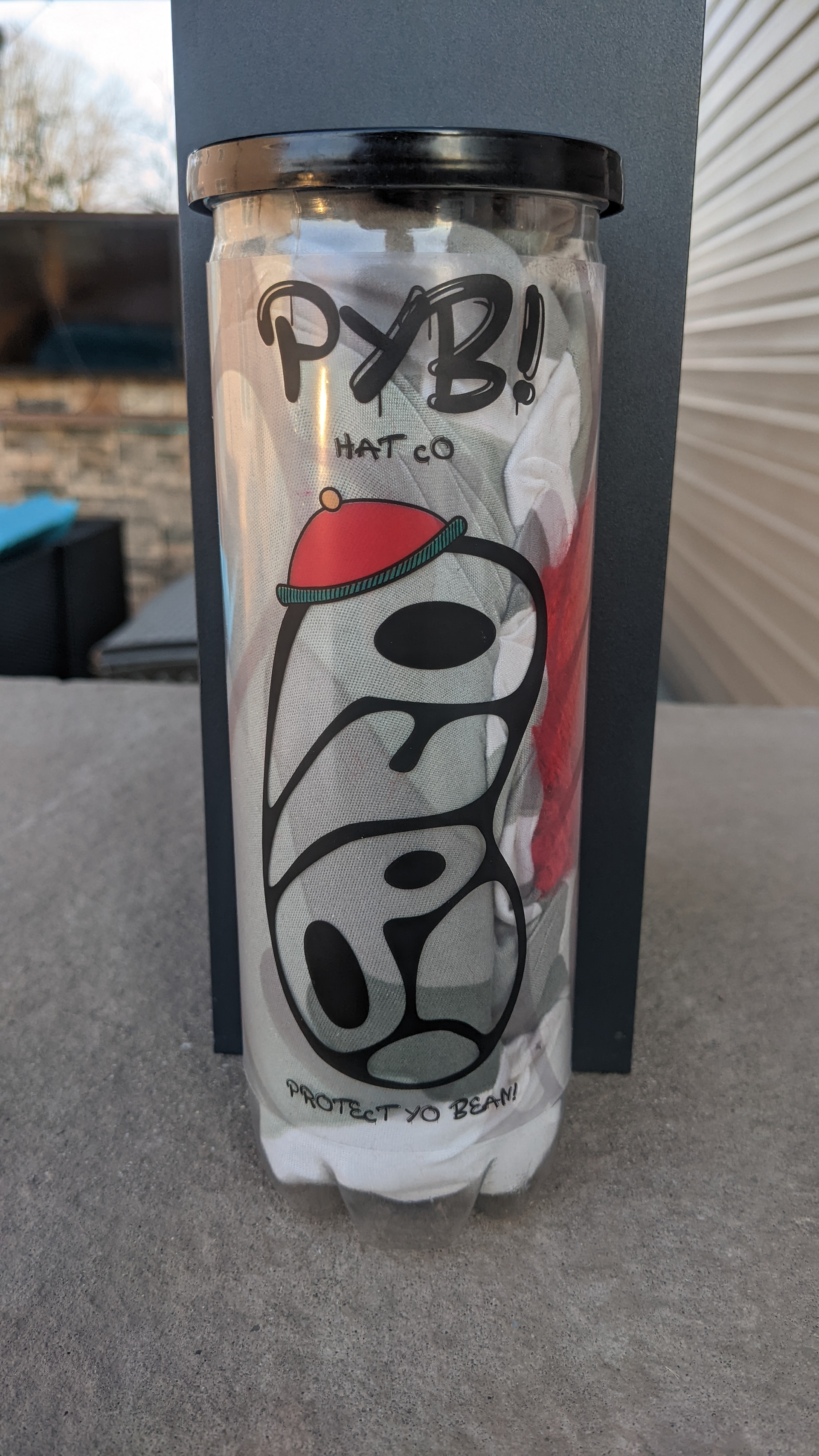

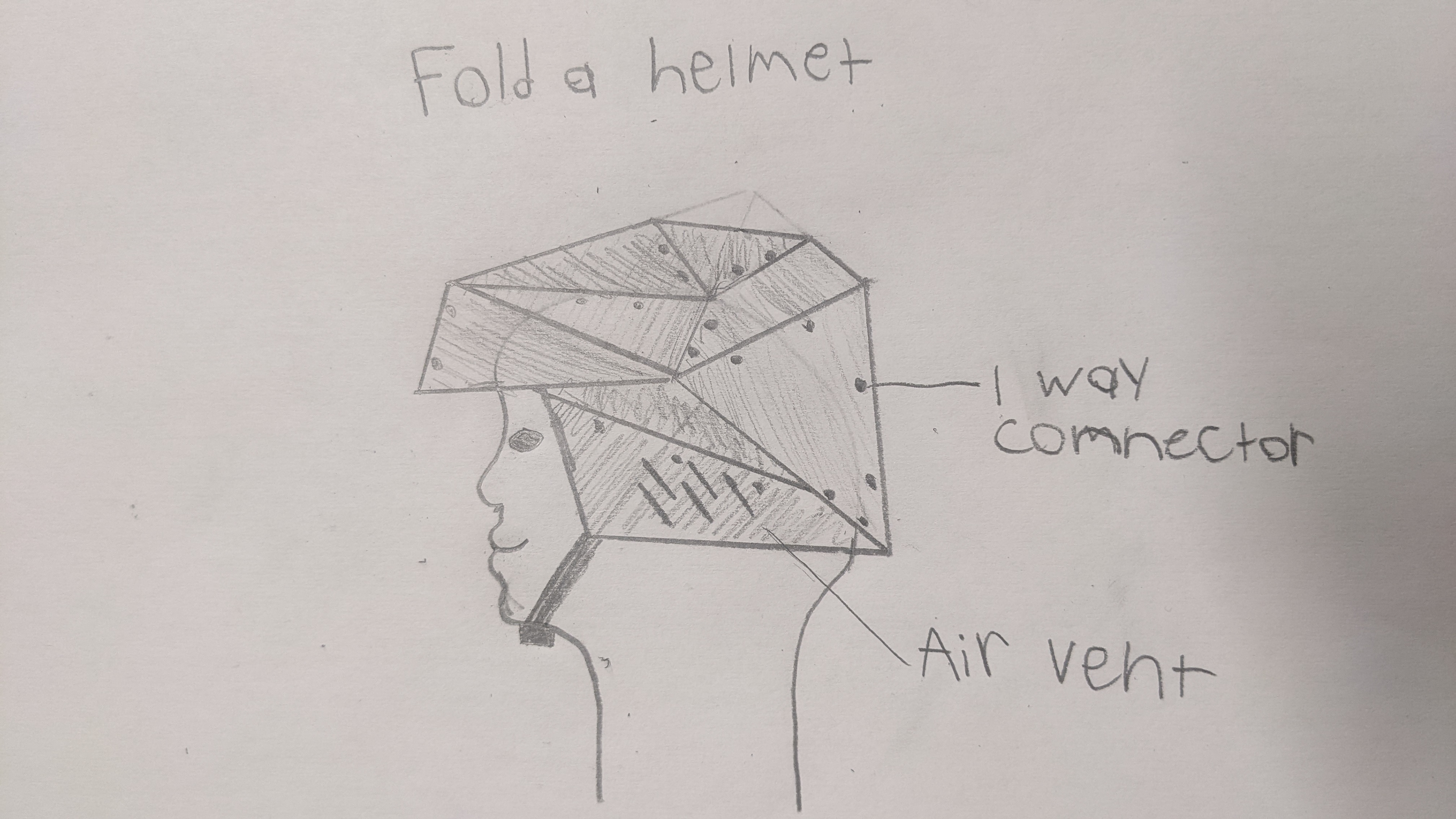

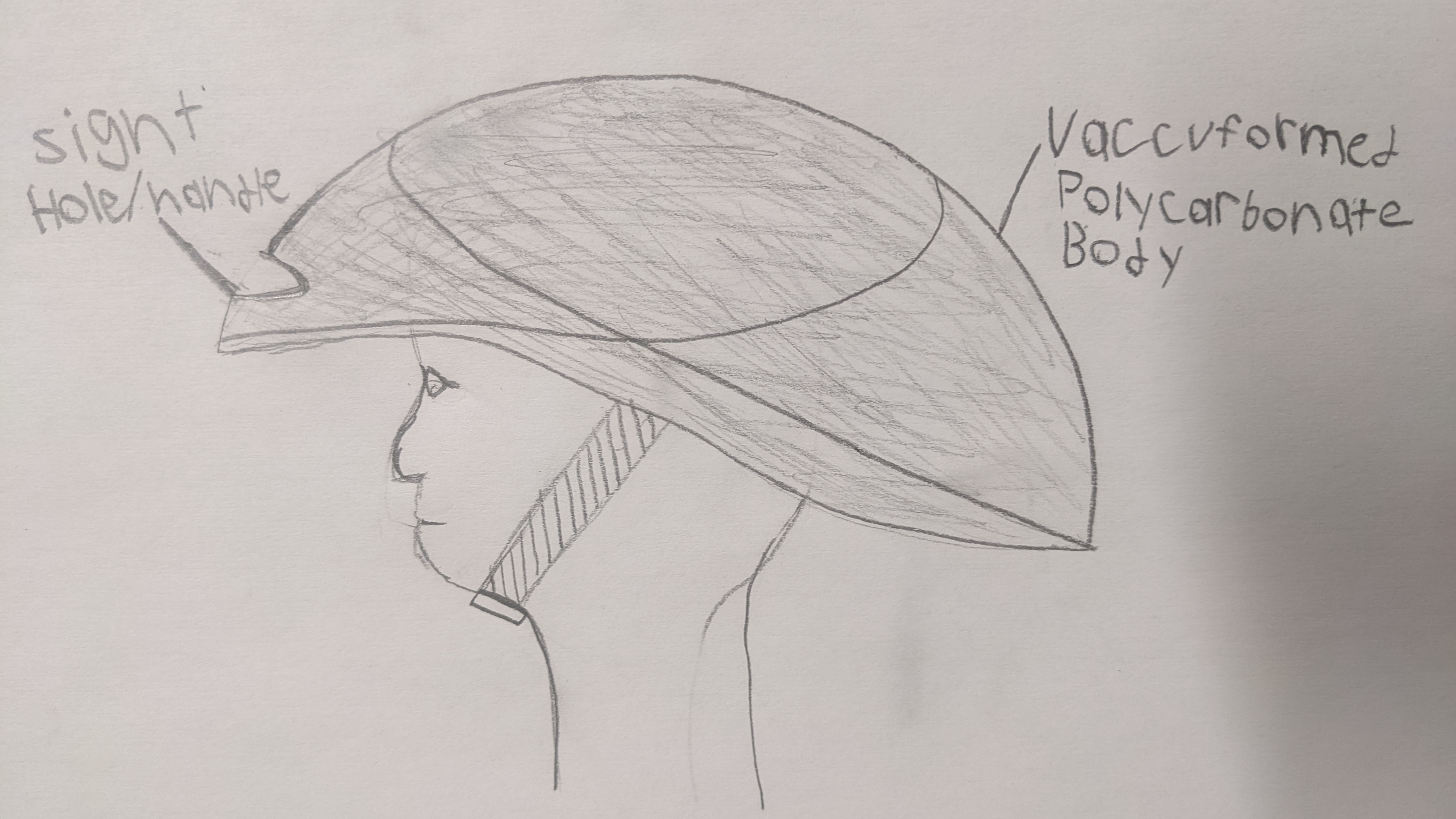

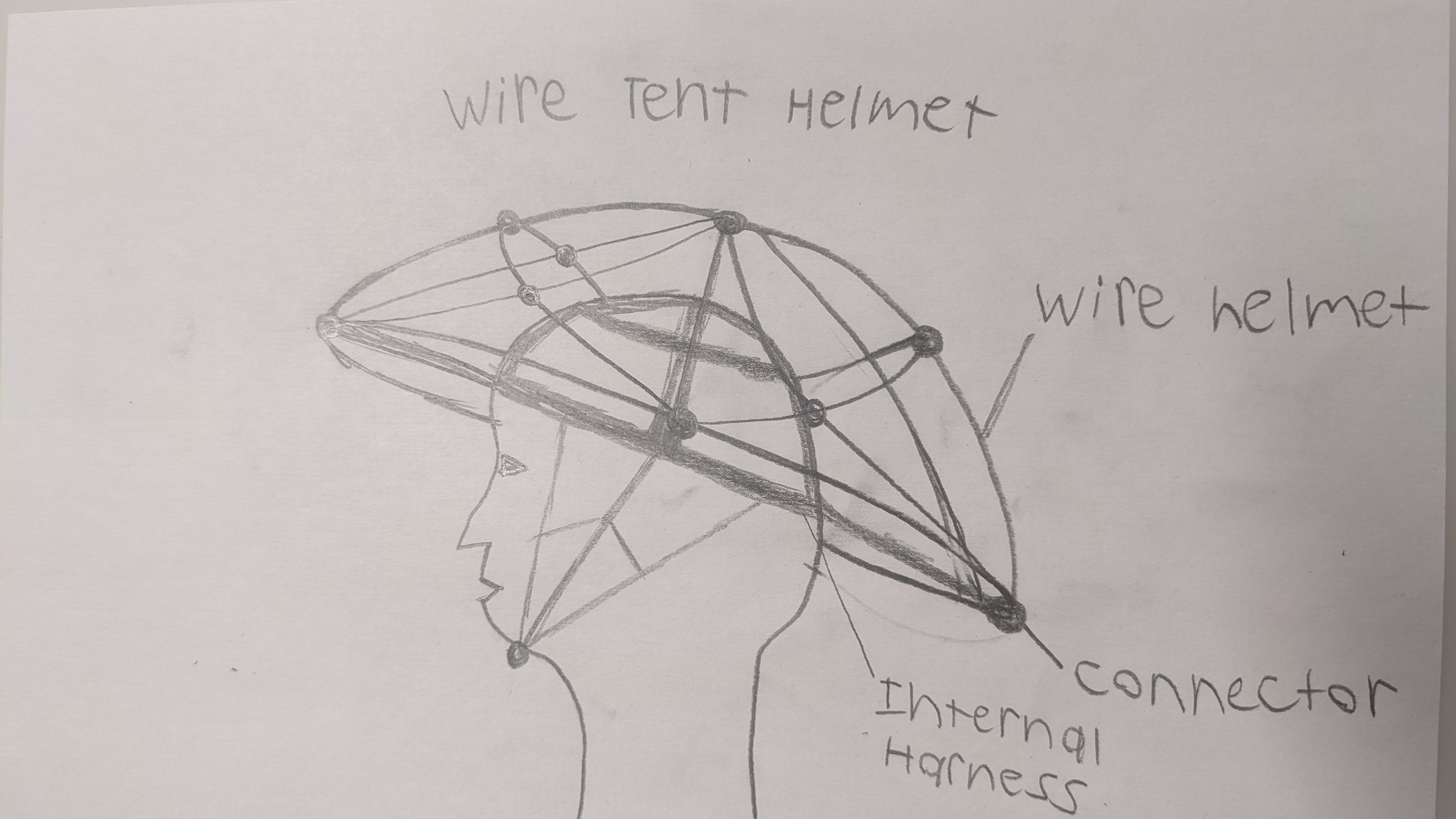

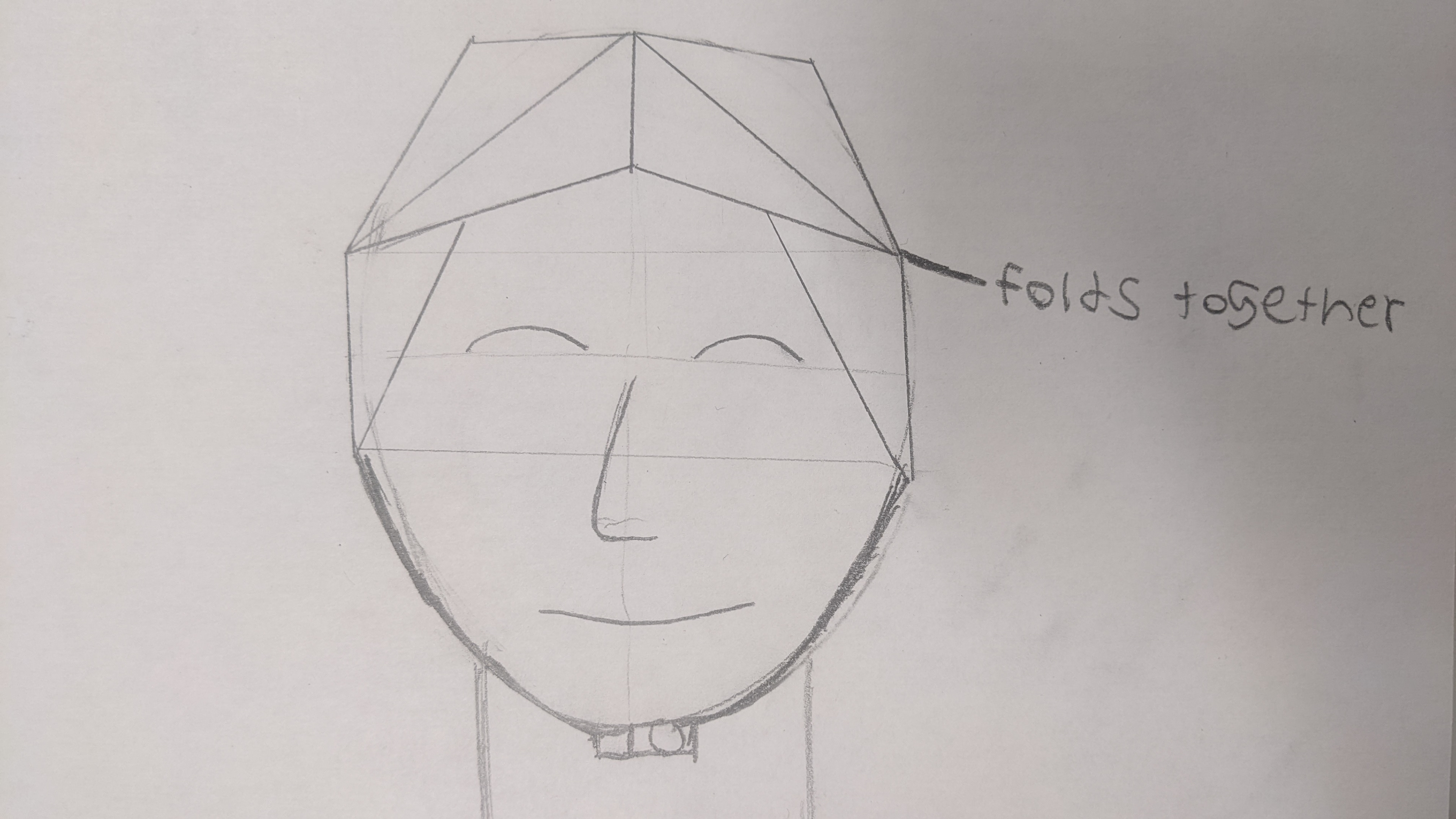

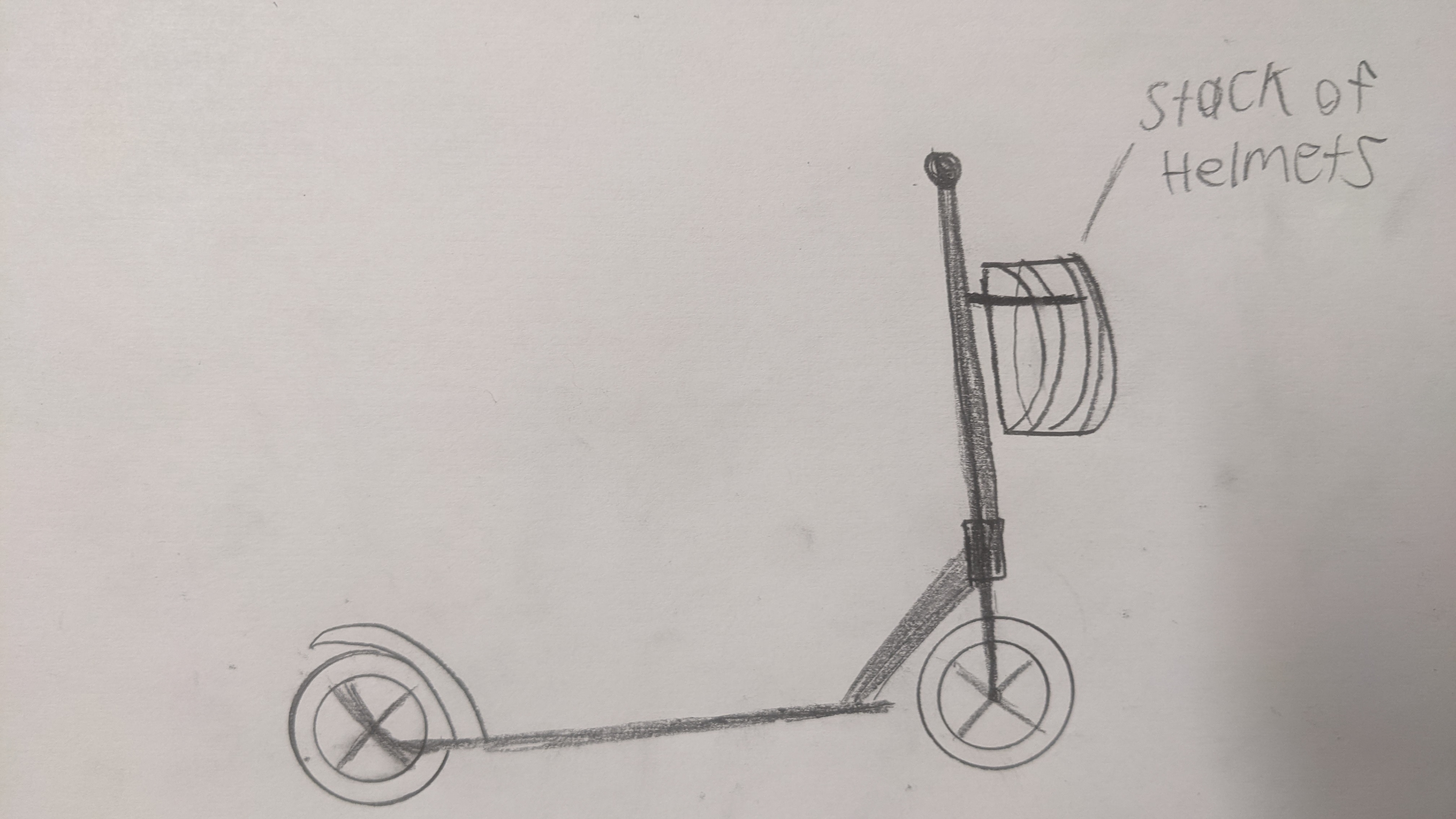

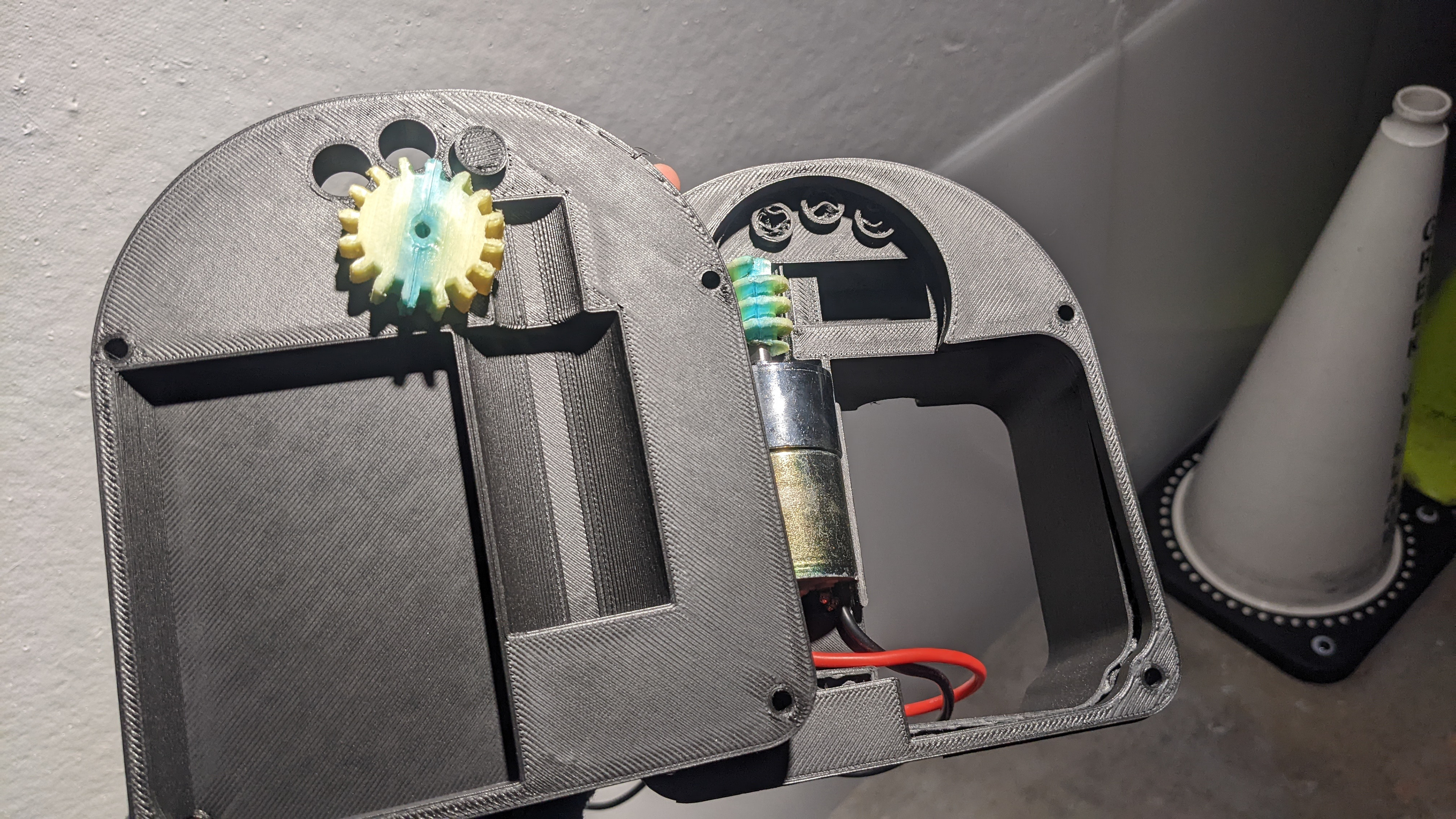

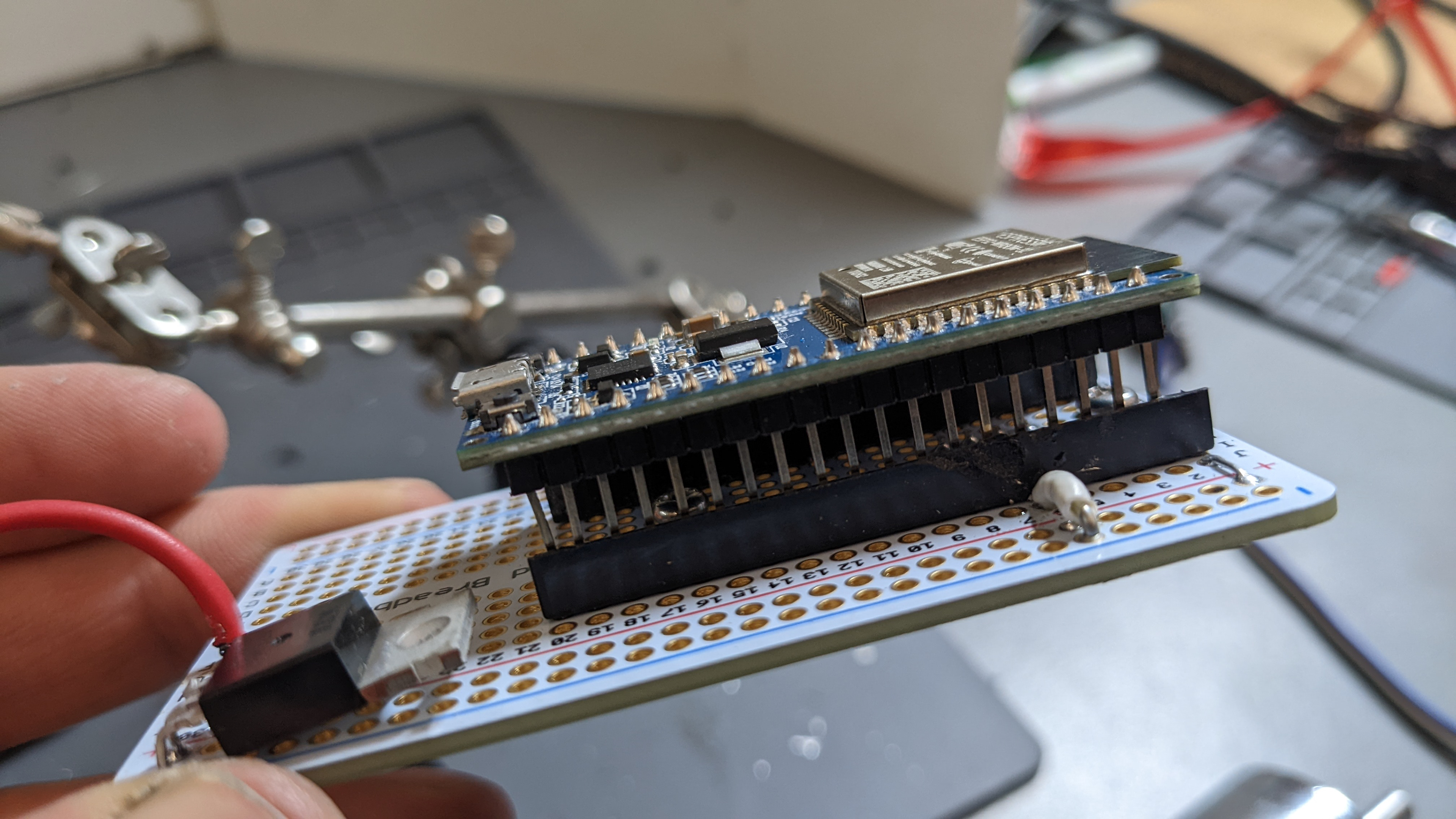

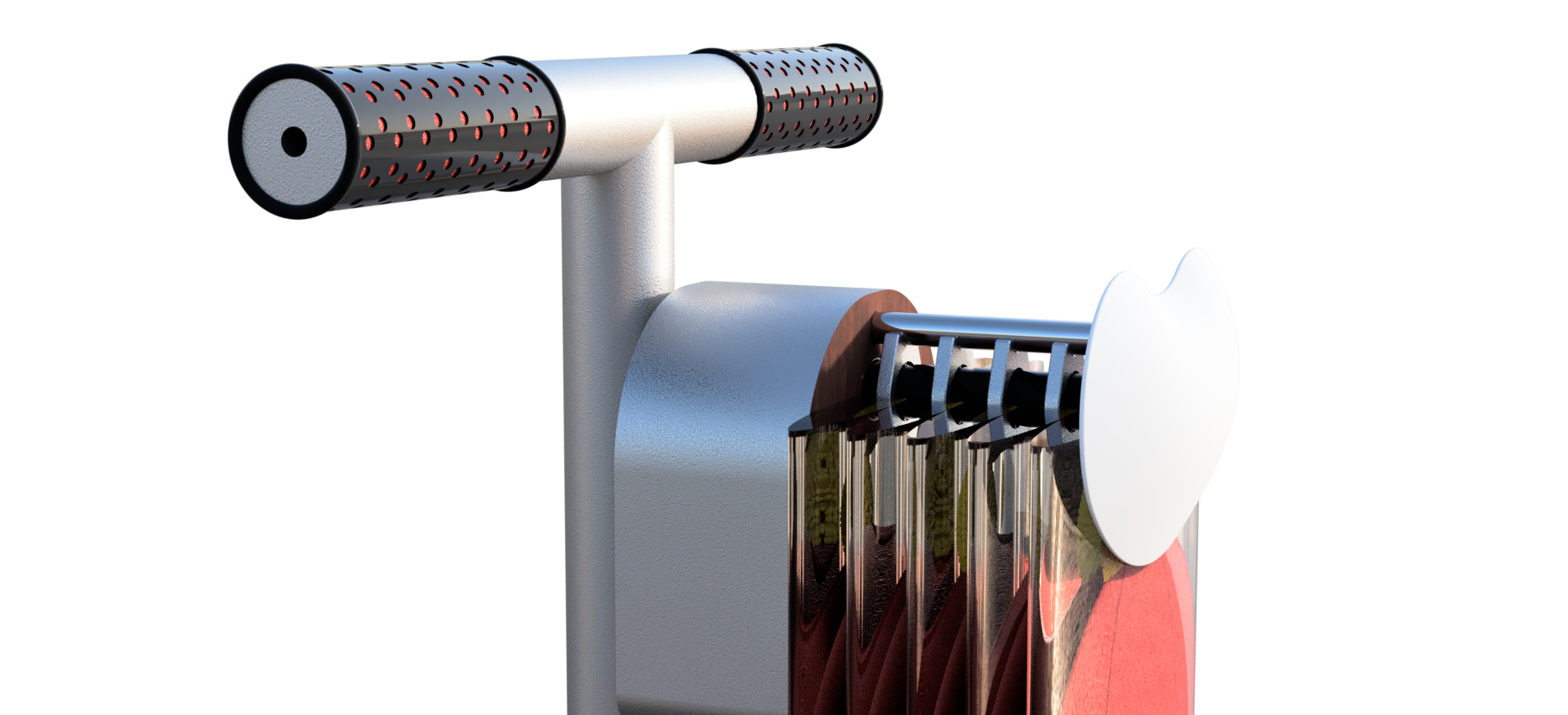

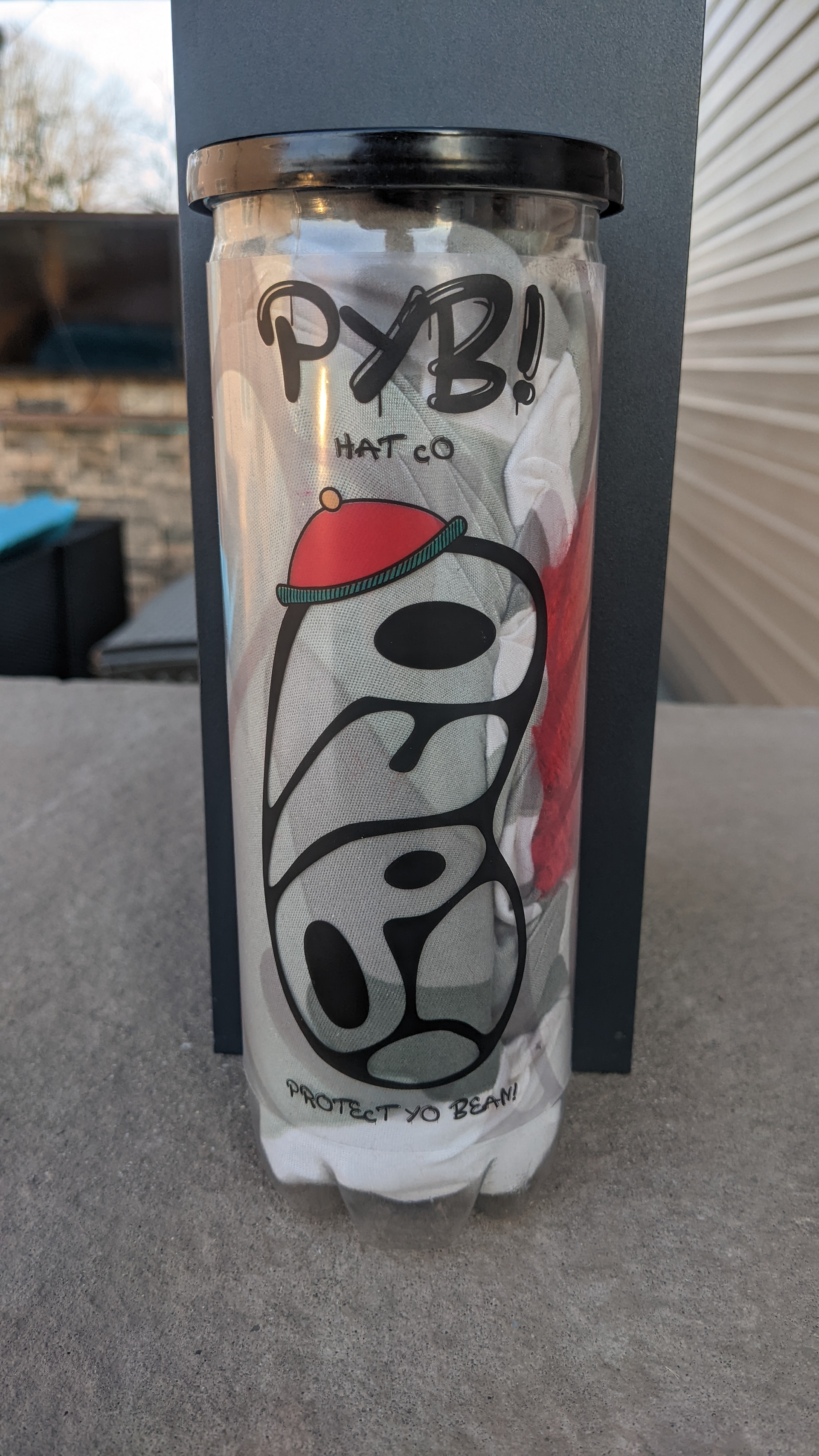

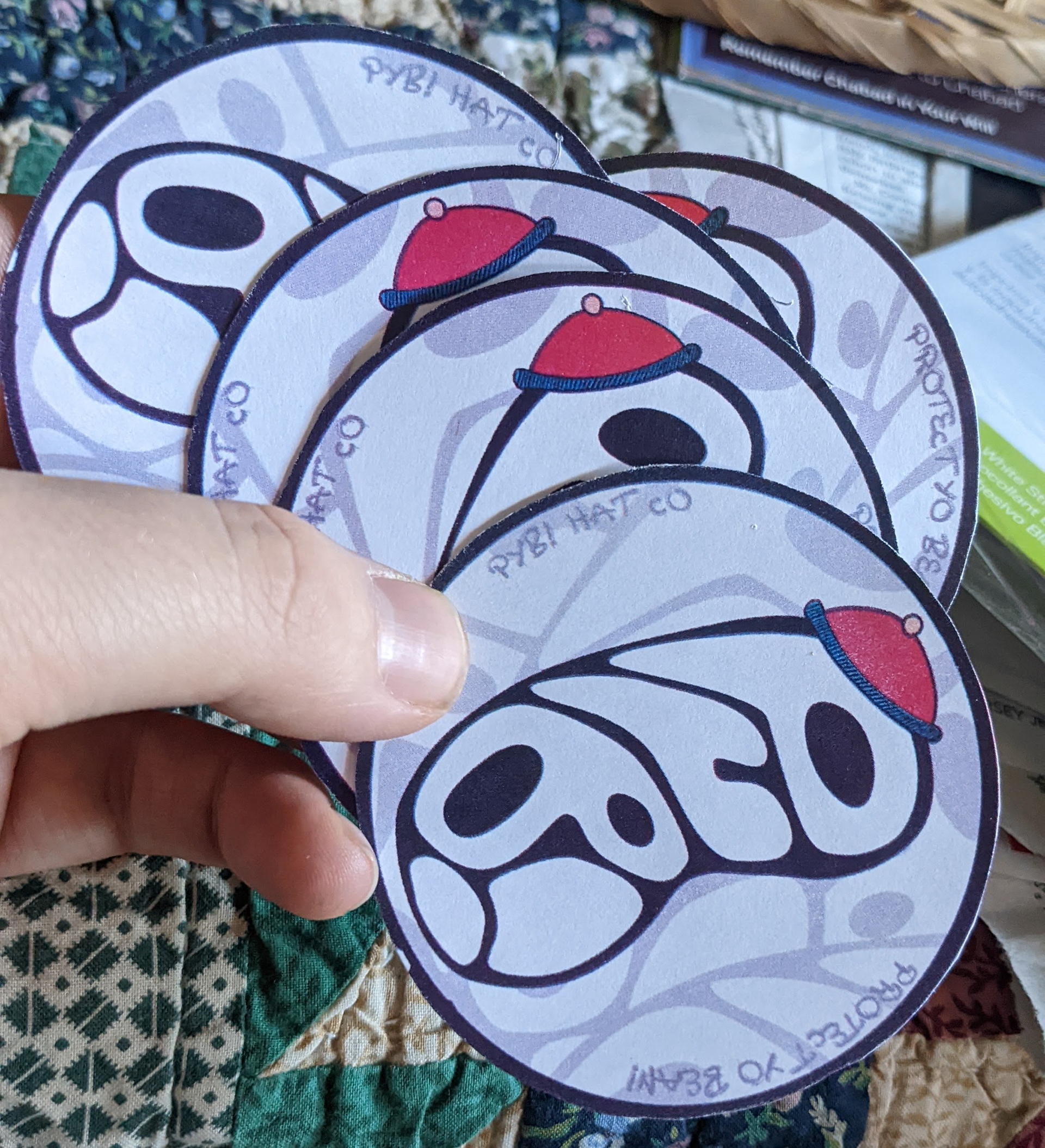

Assignment- Identify a market opportunity and create a company and product that is ready to be launched. A focus on branding was made in addition to normal design. The Pyb Helmet came out of a "motion" studio. My Idea was to protect people's heads while they ride rental E-Scooters or commute via personal mobility devices via easily packable helmets. Most Rentals do not come with a helmet, my research showed that even if provided many do not wear them because they don't like the look or comfort. The PYB is designed to provide an alternative form of head protection that can be used to reduce impacts on a user's head while being very packable and dispensable from E-scooters.

This was a poster I made to describe my project